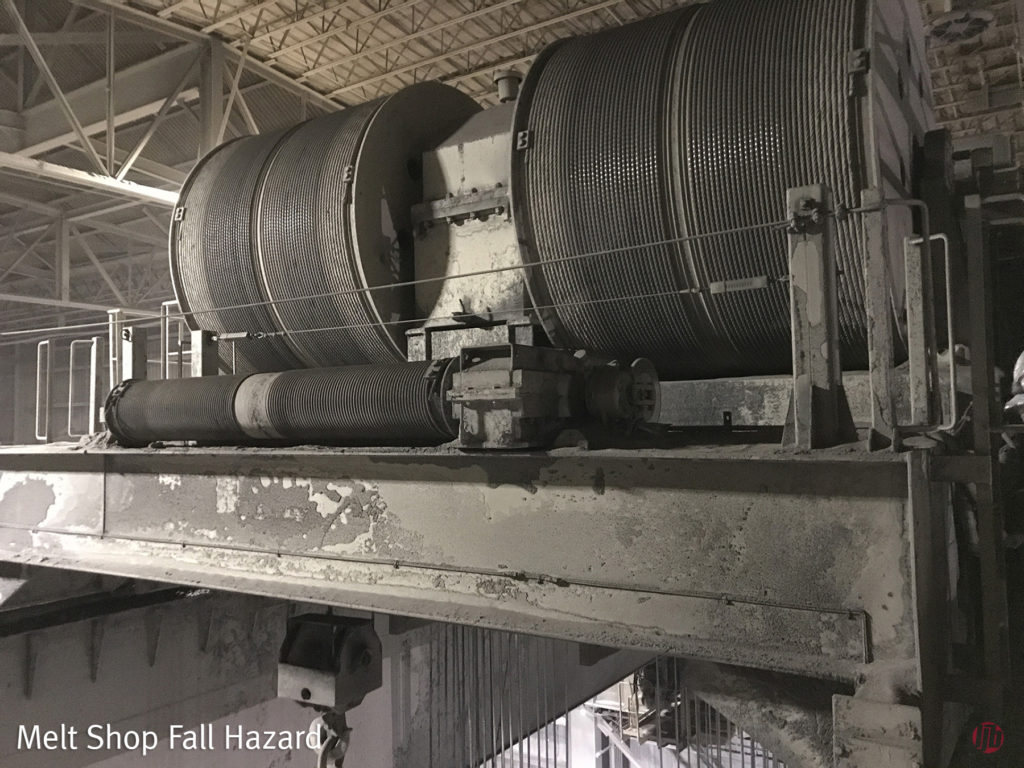

The extreme, high heat environment within any melt shop in the steel industry requires all equipment to be designed and engineered with the environment in mind. After a routine inspection discovered a failure on a piece of fall protection equipment that is intended to save lives—and is located 120 feet above the lower level—the organization knew something needed to change.

In situations like these—when the best fall protection solution is not obvious or cannot be agreed upon—LJB guides organizations through a conceptual design phase to determine a final solution that will provide protection for the worker. This approach generates visualization of the options, develops objective risk, evaluates ease of use, costs, and maintenance criteria, and helps achieve buy-in from key stakeholders before a significant investment is made in final design or equipment purchases.

Providing safe access to the crane trolley and associated work areas includes several complex fall protection elements: It is heavily congested, access is complex, and multiple fall hazards need to be addressed by a coordinated solution. To complete the conceptual phase for this project, LJB researched possible abatement options and prepared conceptual solutions. Along with descriptions and visualizations of the options, the conceptual design report included a summary of advantages and disadvantages and an objective evaluation of the proposed solutions.

With input from stakeholders, LJB developed final conceptual solutions to abate fall hazards associated with performing maintenance on the bridge, end trucks and trolley of the melt shop crane. The new solutions provide increased safety, which not only protects the life of the workers, but also protects the organization from significant financial and legal risk if a fall incident were to occur.