Introduction

Fall protection is a critical aspect of workplace safety, especially in industries where employees are exposed to heights. As we wrap up the fall protection program blog series, we’ll look at how you can ensure continuous improvement and smooth operations.

In this post, we’ll cover:

- Fall Protection Program Implementation and Management Requirements

- Incident Investigation and Reporting

- Written Fall Protection and Rescue Procedures

- Program Evaluation

Fall Protection Program Implementation and Management Requirements

Hazard abatement isn’t the end of the road. While it’s a huge step, you’ll need to manage and implement the systems you put in place.

Here’s what to focus on:

Preventing and Controlling Fall Hazards in New Facilities

You may have taken care of fall hazards at one facility, but are you building more sites or renovating others? The planning and design phase is a great time to address hazards and develop elimination or control options, so you don’t have to deal with them later with increased costs.

Design and Use of Fall Protection Systems

Ensure your Personal Protective Equipment (PPE)-based fall protection systems have been properly designed and installed and do what they’re supposed to. For example, fall arrest systems limit the maximum arrest force to 1,800 pounds or less, adequate clearance is calculated, and travel restraint systems are limited to surfaces with less than a 4:12 slope.

Selection and Use of Anchorage Systems

All anchorages must be either certified by a Qualified Person or selected by a Competent Person.

Equipment Inspection, Maintenance, and Storage

All equipment must be inspected before each use by an Authorized Person (the person who is using the equipment) and at least every year—or as defined by an equipment manufacturer—by a Competent Person, or Competent Rescuer. Additionally, equipment should be permanently taken out of service if it’s deemed necessary through the inspection process.

Summoning Rescue Services

If an incident does occur, what are the next steps? Organizations must have a documented plan for summoning both internal and external rescue as needed.

Incident Investigation and Reporting

In the event of an incident, you’ll want to investigate and report back to your organization’s leadership team. The goal is to get down to the root cause of the incident. You could have gaps in policies, procedures, training, and/or equipment. Here are four steps to follow as soon as possible after the incident:

- Document and record the incident

- Determine whether worker training should be modified

- Inspect or discard equipment components and overall system

- Review whether procedures worked or could better communicate the requirements

The Program Administrator, Authorized Person, Competent Person, and Qualified Person should all be part of this process.

Written Fall Protection and Rescue Procedures

Any time a worker is exposed to a fall hazard while using a PPE-based fall protection system, written fall protection system use and rescue procedures are required. These procedures must:

- Be prepared by a Qualified Person, Competent Person, or Program Administrator

- Be specific for the workplace and task

- Provide for 100% continuous protection for the worker

- Include training requirements

- Include details pertaining to anchorages, fall clearance requirements, use, egress, and limitations

- Include inspection requirements

- Include descriptions of all necessary components

- Include rescue requirements

Program Evaluation

Compliance

Standards and legislation are always changing, so it’s important to make sure you keep your program up to date. Additionally, if you’ve experienced any violations by workers or contractors, you’ll want to dig into why that happened and what can be done to fix it. Was it training, a hazard that wasn’t addressed, not keeping up with standards, something else? Taking time to address these areas will help you increase your compliance moving forward.

Training Effectiveness

Training is one of the most important aspects to address when it comes to fall protection. Did training apply to the roles and responsibilities at your organization? Going straight to the source of those using the training can reveal a lot of information there. Do you have performance evaluations and knowledge checks in place to make sure workers are staying sharp and protecting themselves?

System Use and Inspection

The appropriate use of equipment is crucial, so you’ll want to check up on that along with procedures being used in the field. Take note of how well your equipment is being used. When acquiring new equipment, it’s critical to ensure it meets all necessary safety standards and is compatible with existing systems. How much has that been baked into the procurement process? Do all your systems have as-built drawings for maintenance and inspection along with system certification records to ensure equipment is up to date and compliant with safety standards?

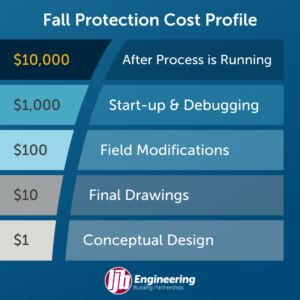

Integration of Fall Protection into Design

How is Prevention through Design (PtD) being utilized at your organization? Addressing fall hazards early on in design phases can drastically reduce costs and keep workers safe. Where do you have opportunities to do this moving forward? This cost profile shows how much fall protection costs according to different phases. Taking time to evaluate and get ahead of future needs can save you a lot of money.

Incident Investigation

If incidents do occur, how well are they being documented? Communication before, during, and after an incident should be happening as well.

If you want to evaluate how effective your fall protection program is today, download a free assessment tool HERE.

Next Steps

A well-managed fall protection program is essential for ensuring the safety of employees and maintaining compliance with industry standards. By regularly handling these management tasks, you can enhance safety and promote a culture of continuous improvement. Remember, the goal is not just to meet regulatory requirements but to create a safer and more productive workplace for everyone.

Thank you checking out our fall protection program blog series. If we can answer any questions for you, feel free to reach out HERE!